Between hotter summers and stricter carbon targets, British buildings are learning to keep their cool more intelligently. The UK’s housing stock-designed to hold heat-now faces more frequent heatwaves, while businesses and homeowners alike navigate high electricity prices, tightening refrigerant rules, and the practicalities of decarbonisation. In this landscape, air conditioning is shifting from a seasonal afterthought to a strategic asset that must deliver comfort, curb energy use, and play nicely with an increasingly digital grid.

2025 will be defined less by bigger units and more by smarter ones. Efficiency gains are arriving through refined inverter technology and heat-recovery designs, while reversible heat pumps blur the line between cooling and low‑carbon heating. Controls are becoming predictive rather than reactive, using sensors, tariffs, and weather data to trim demand without sacrificing comfort. At the same time, the move to lower‑GWP refrigerants, better system integration with ventilation and renewables, and data‑driven maintenance is reshaping how systems are specified and operated.

This article explores the top five air conditioning trends set to matter most in the UK for 2025-where energy efficiency meets smart cooling, and every kilowatt counts. For all new setups, choosing a professional provider for AC installation is the crucial first step.

Table of Contents

- Smart controls, zoning and AI optimisation for UK homes and offices: choose open protocols, enable tariff based schedules and calibrate occupancy sensors for real savings

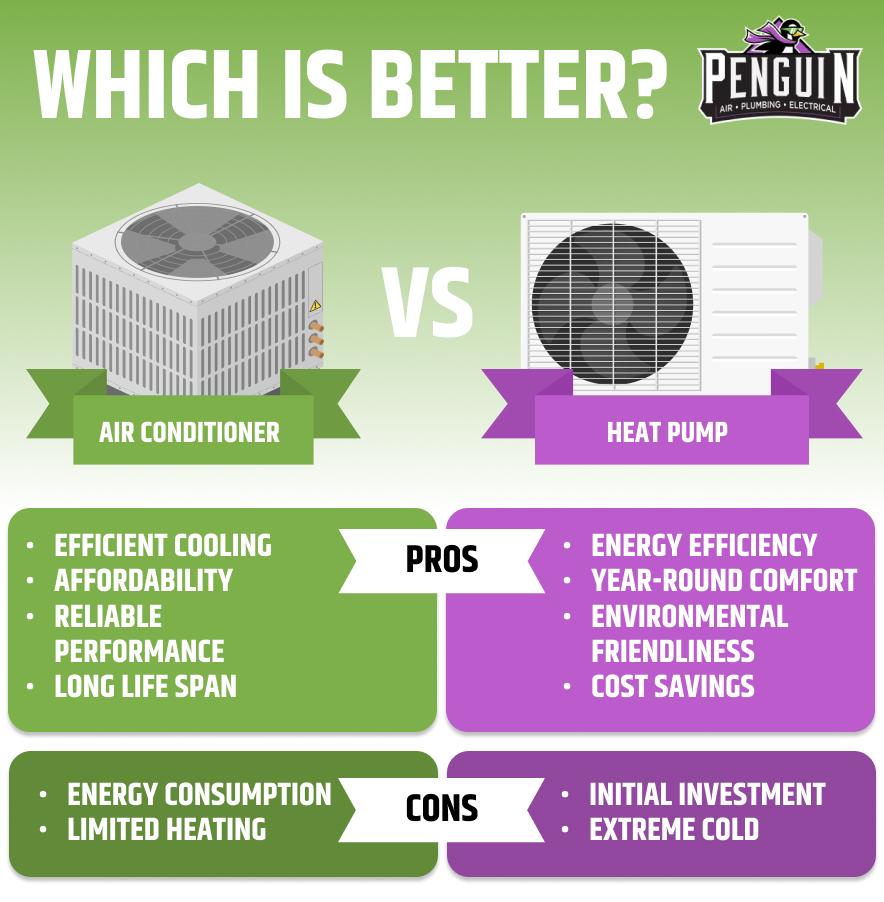

- Heat pumps and heat recovery VRF for efficient cooling and year round comfort: target high SEER and SCOP, specify inverter driven units and prioritise professional right sizing

- Low GWP refrigerants and F gas phase down readiness: evaluate R290 and R454B options, plan safe installation clearances and implement continuous leak detection

- Grid aware and solar assisted cooling: integrate PV and batteries, use load shifting and pre cooling to lower bills and emissions during summer peaks

- Insights and Conclusions

Smart controls, zoning and AI optimisation for UK homes and offices: choose open protocols, enable tariff based schedules and calibrate occupancy sensors for real savings

Smart cooling in the UK now means orchestrating devices, not just swapping boxes. Specify controllers and thermostats that speak open standards (BACnet/IP, Modbus, KNX, Zigbee/Matter over Thread) so your VRF, splits and hybrid heat pumps can share data and avoid lock-in. With an API and a common bus, an AI layer can adjust setpoints by zone, exploit time‑of‑use tariffs (Agile, Economy 7) for pre‑cooling and mild thermal storage, and cap compressor load during red‑rate periods. Offices benefit from smart dampers, VAV or FCU grouping to end over‑conditioning; homes gain from per‑room schedules, adaptive deadbands and window/contact lockouts that protect comfort without wasting kWh.

- Choose open protocols: native BACnet/Modbus/KNX or Matter; bridge to MQTT/REST for BMS or home hubs.

- Enable tariff logic: import live unit rates, pre‑cool off‑peak, widen deadbands at peak, and set demand caps.

- Calibrate occupancy sensing: pair PIR with mmWave, set 5-10 min timeouts, filter false triggers, and use CO₂ for meeting rooms.

- Zone smartly: smart vents or VAV for ducted systems; FCU group control; priority overrides for critical spaces.

- Keep resilience: local fallbacks, encrypted comms, role‑based access, and clear data ownership.

| Scenario | Open protocol | Tariff link | Zoning method | Est. saving | Payback |

|---|---|---|---|---|---|

| 2-3 bed home | Matter + MQTT | Octopus Agile | Smart vents + room stats | 10-20% | 9-18 mo |

| Small office (30-60 desks) | BACnet/IP | ToU import | VAV + meeting overrides | 15-30% | 12-24 mo |

| Multi‑let floor | KNX ⇄ BACnet | Fixed ToU | FCU groups + CO₂ priority | 18-35% | 18-30 mo |

Real savings depend on commissioning. Map thermal zones, balance airflow, and run A/B week tests to tune deadbands, setback limits and ramp rates. Calibrate sensors in situ (desk height, away from supply air, verify with spot readings), then let the control loop learn: weekday vs. weekend patterns, weather forecasts, and occupancy probabilities. Keep guardrails-min/max setpoints, max ramp per 15 minutes, and humidity bounds-to protect comfort and fabric. Track KPIs like kWh/m², COP/EER, and “comfort minutes,” review quarterly, and schedule seasonal retuning; with open data you can switch algorithms or vendors later without ripping out hardware.

Heat pumps and heat recovery VRF for efficient cooling and year-round comfort: target high SEER and SCOP, specify inverter-driven units and prioritise professional right sizing

Air-to-air heat pumps and modern heat recovery VRF are reshaping comfort as electricity gets cleaner. By shifting heat rather than generating it, they deliver quiet, stable cooling in summer and efficient heating in winter, while balancing rooms that need different temperatures at the same time. Target systems with genuinely high seasonal ratings-SEER for cooling efficiency and SCOP for heating performance-because real savings happen across part-load hours, not just at full tilt. Pair this with inverter-driven compressors and fans for ultra-fine modulation, low noise, and smooth humidity control, and you’ve got a system that feels as good as it performs. Remember that while AC systems can heat, regular checks of traditional appliances are still vital; don’t forget your scheduled boiler service and repair.

- Inverter-first specification: Look for wide modulation ranges and low minimum capacities for steady-state comfort.

- High seasonal ratings: Aim for SEER 20+ and SCOP 4.0+ where site and budget allow.

- Heat recovery: Reuse internal “waste” heat between zones to cut compressor hours.

- Smart controls: Zoning, occupancy sensing, and adaptive setpoints beat fixed schedules.

- Low-GWP refrigerants: Consider R32/R454B options and ensure leak detection and safe design.

| System | SEER (typ.) | SCOP (typ.) | Best Use |

|---|---|---|---|

| Single-split heat pump | 20-25 | 4.2-5.1 | Rooms & small homes |

| Multi-split | 18-23 | 4.2-5.0 | Apartments & light retail |

| Heat recovery VRF | 18-22 | 4.0-4.8 | Mixed-use, offices, hotels |

Performance hinges on professional right sizing. Oversized units short-cycle, waste energy, and struggle with humidity; undersized systems grind, drift from setpoint, and raise noise. Demand a room-by-room heat gain/loss calculation, diversity allowances for VRF, verified airflow, and commissioning data (refrigerant charge, superheat/subcool, fan curves). Round it out with predictive maintenance (filters, coils, drain hygiene), metering for seasonal COP verification, and clear controls handover so users actually benefit from the efficiency you specified-365 days a year.

Low GWP refrigerants and F gas phase down readiness: evaluate R290 and R454B options, plan safe installation clearances and implement continuous leak detection

With the UK F‑gas phase down tightening in 2025, many projects are pivoting to ultra‑low GWP choices that balance carbon impact with practical deployment. Two front‑runners are R290 (propane, GWP ≈ 3, A3) and R454B (GWP ≈ 466, A2L). R290 shines in monobloc and outdoor DX cabinets where charge can be contained and mitigations are straightforward; indoor split AC remains constrained by charge-per‑volume limits and floor‑area rules in IEC 60335‑2‑40 and BS EN 378. R454B offers a familiar R410A‑like envelope with lower GWP than R32, easing adoption across new splits, rooftops and light chillers while maintaining serviceability. Make the call using whole‑life criteria: carbon, part‑load efficiency, ambient profile, occupancy density, charge per m³, and contractor competence for A2L/A3 handling under UK guidance.

Safety moves from checkbox to strategy. Define equipment siting and installation clearances early: honour manufacturer keep‑out zones, segregate from ignition sources, and route refrigerant lines to minimise accumulation in occupied spaces. Prioritise outdoor siting or factory‑sealed appliances for A3, and apply leak‑limiting measures for A2L indoors. Bake in continuous leak detection: place sensors low to the floor and near potential pockets, alarm at 10-25% LFL, auto‑isolate circuits, stop indoor fans, start purge/ventilation, and push events to BMS with maintenance logs. Finish with witnessed commissioning, bump tests and a calibration plan aligned to sensor manufacturer intervals.

- Selection: Map load profile, refrigerant charge, floor area and occupancy to choose between R290 and R454B.

- Design: Reserve clearances, define no‑ignition zones, and detail pipework gradients and drip‑tray ventilation.

- Controls: Integrate leak alarms with fan stop, valve close and fresh‑air purge; log to BMS.

- Electrical: Use appropriately rated components in classified zones; verify earthing and bonding.

- Commissioning: LFL setpoint verification, bump tests, QR‑coded O&M, and scheduled sensor calibration.

| Attribute | R290 | R454B |

|---|---|---|

| GWP (approx.) | ~3 | ~466 |

| Class | A3 (highly flammable) | A2L (mildly flammable) |

| Best fit | Monobloc, outdoor DX | Splits, rooftops, small chillers |

| Clearance focus | Ignition exclusion zones | Occupant area charge limits |

| Leak detection | Low‑level, rapid isolation | Low‑level, fan stop + purge |

| Pros | Very low GWP, high efficiency | Good efficiency, easier adoption |

| Watch‑outs | Charge limits indoors | Training, A2L toolchain |

Grid aware and solar assisted cooling: integrate PV and batteries, use load shifting and pre cooling to lower bills and emissions during summer peaks

Air conditioners are learning to read the day like a weather-savvy concierge: when the sun is high and your PV is overflowing, they cool the home a touch deeper; when the evening peak arrives, they glide on stored energy and a slightly relaxed setpoint. Pairing a smart, inverter-driven system with a home battery enables pre-cooling and load shifting that trims the 4-7 pm spikes common on UK time-of-use tariffs, while following live grid signals (price or carbon intensity) to prioritise the lowest-cost, lowest-carbon kilowatts. The result is steadier comfort, quieter compressors, and higher self-consumption of rooftop generation-without the sweaty scrambles when demand surges.

- Comfort-first logic: nudge the setpoint earlier in the day to “store coolth” in the building fabric.

- Battery-aware control: reserve state of charge for the peak; avoid draining on cheap midday solar.

- Tariff tracking: integrate with dynamic rates (e.g., Agile-style) to auto-shift runtime.

- Carbon-smart timing: align cooling with low grid intensity windows for verifiable emissions cuts.

| Time | Setpoint | Power Source | Goal |

|---|---|---|---|

| 11:00-15:00 | -1°C pre-cool | PV surplus | Store “coolth”, protect battery |

| 16:00-19:00 | Normal + smart fan | Battery + low compressor | Glide through peak |

| 19:00-22:00 | Comfort hold | Grid + remaining PV | Evening comfort |

| 22:00-07:00 | Eco mode | Off-peak grid | Quiet top-up, recharge |

Set-up is straightforward: choose a Wi‑Fi-enabled AC/heat pump with granular scheduling, connect it to a smart meter and your PV/battery app, then automate rules such as “pre-cool when solar export > X kW” or “hold battery SOC > 50% from 15:30.” Combine gentle fan-only circulation with shading to keep gains low, and watch humidity-small, earlier adjustments beat deep evening blasts that risk clamminess. Many systems now integrate with platforms like Home Assistant and offer API hooks for tariff and carbon data, so your cooling strategy can evolve with the forecast, not fight it.

- Kit checklist: inverter AC, PV monitoring, battery with schedulable SOC, TOU tariff, smart thermostat.

- Targets: cut peak import by 30-60%, lift PV self-use, smooth indoor temps by 0.5-1.0°C.

- Fine-tuning: start pre-cooling 60-120 minutes before peak; tweak by room mass and glazing.

Insights and Conclusions

As the UK’s summers grow warmer and the grid grows smarter, cooling is becoming less about brute force and more about finesse. The trends shaping 2025 point in the same direction: systems that sip energy, learn from your habits, play nicely with the grid, and tread lighter on the planet. In short, the coolest kilowatt-hour is the one you never have to use.

Whether you’re managing a portfolio or upgrading a single flat, the choices you make this year will set the tone for the next decade of comfort and cost. Keep an eye on evolving standards and incentives, pair smart controls with solid fabric improvements, and ask hard questions about lifetime performance-not just headline efficiency. Pilot, measure, iterate, and let data guide the next step.

Cooling in 2025 isn’t a gadget; it’s a strategy. If you align today’s decisions with tomorrow’s regulations, tariffs, and weather, you won’t just keep spaces comfortable-you’ll keep options open. A cool-headed approach, indeed.